| Dear Nazarbaeyv University Community!

NURIS is contributing to the fight against COVID-19 pandemic by setting up mass production of protective masks using press molds.

In early June masks were delivered to medical institutions with an urgent need for personal protective equipment in Nur-Sultan, Kyzylorda, Shymkent, Turkestan, and Karaganda. NURIS Machine Shop employees Yerken Bektassov, Bekzat Tilegen, Ranil Ibragimov, Nurzhan Malikov, Andrey Sidorov and ITS employees Askar Sharipov and Talgat Makenov worked on the development and production. We appreciate their contribution and important work during the pandemic.

The protective equipment manufacture consisted of 7 stages:

| |

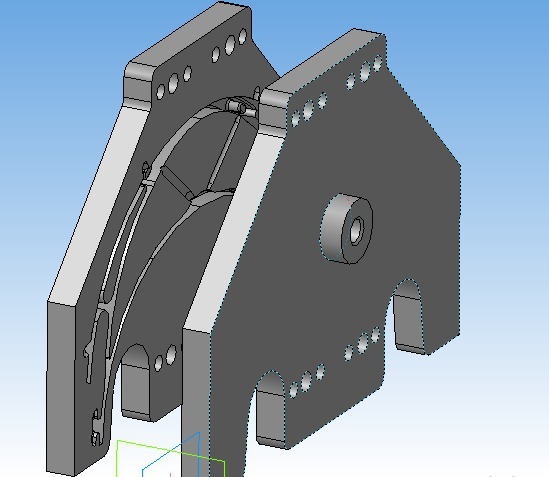

|  | | | | Stage 1. 3D mold model manufacture.

The Design Department using the modern Siemens NX 3D Modeling CAD Complex designed a 3D mold model for casting a protective screen made of plastic. The filling material is polypropylene. Its characteristics are ideal for a protective screen. After that, the 3D model was handed over to a process engineer for manufacturing on a 5-axis DMU-50 machine.

| |  | | | | Stage 2. Mold making

The control program for DMU-50 5-axis CNC machining center was preliminarily written.

After loading the program on this center, the tool and the billet of aluminum sheet with a thickness of 30 mm are installed, then high-precision processing of the part is performed.

After the mold manufacture, control measurements are performed.

| |  | | Stage 3. Mold testing on the injection molding machine

Mold was tested on the injection molding machine. The first tests detected deficiencies: insufficient filling at the extreme points; in some places, the angle of inclination is insufficient to remove the part from the mold; removing the part from the mold manually is practically not feasible – there is a need for a mechanical ejector; the ejector will have nowhere to rest when opening the mold, additional guides and an adjustable stop must be installed on the injection molding machine.

After testing, the mold was sent for follow-up.

| |  | | Stage 4. Mold follow-up

The follow-up process was not easy, it was necessary to re-adjust the mold on DMU-50 machine. In parallel, a mechanical ejector was prepared.

As a result, the assembled mold design with a mechanical ejector was ready for final testing.

| |  | | | | Stage 5. Mold control testing

Control tests were carried out on the injection-molding machine at the required mode. After filling in the plastic and adding dye, the casting process began.

The entire casting process was stable, and we started getting ready parts one by one. Measurements of samples showed that the dimensions correspond to the drawing of the finished part.

But that's not all! It is necessary to make another mold for a protective mask cover.

⠀

| |  | | | | Stage 6. Manufacturing and testing of the mold for the protective mask cover.

After manufacturing the first mold, we took into account the entire technological process, which allowed us to manufacture the second mold in the shortest possible time. The process of machining and manufacturing the cover mold is similar to the process of manufacturing the first mold. After the manufacture of the mold on the machine, the necessary measurements and tests were carried out.

| |  | | Stage 7. Assembling the protective mask ⠀

All components are made: transparent sheets of the mask are cut on the Epilog Laser's Fusion laser engraving machine, the rim and lids are cast from polypropylene on the injection-molding machine using molds, and the elastic bands are cut according to a template.

Next is the assembly of the protective mask and packaging for sending to medical institutions.

| | |

| To date, 580 protective masks have been produced. The need for protective masks is growing, so the process of manufacturing, assembling and supplying ready-made personal protective equipment continues. | |

| NURIS Machine Shop offers a wide range of services for the design and manufacture of experimental equipment for research and development, as well as prototypes of innovative products.

If you have an idea, you can always contact our managers for advice by sending a request by email machineshop@nu.edu.kz.

| |

| Innovation cluster of Nazarbayev University Nur-Sultan city, 53, Kabanbay batyr Ave. Tel: +7(7172)70 66 43, 92 99 nuris_cluster@nu.edu.kz |  | |

| |